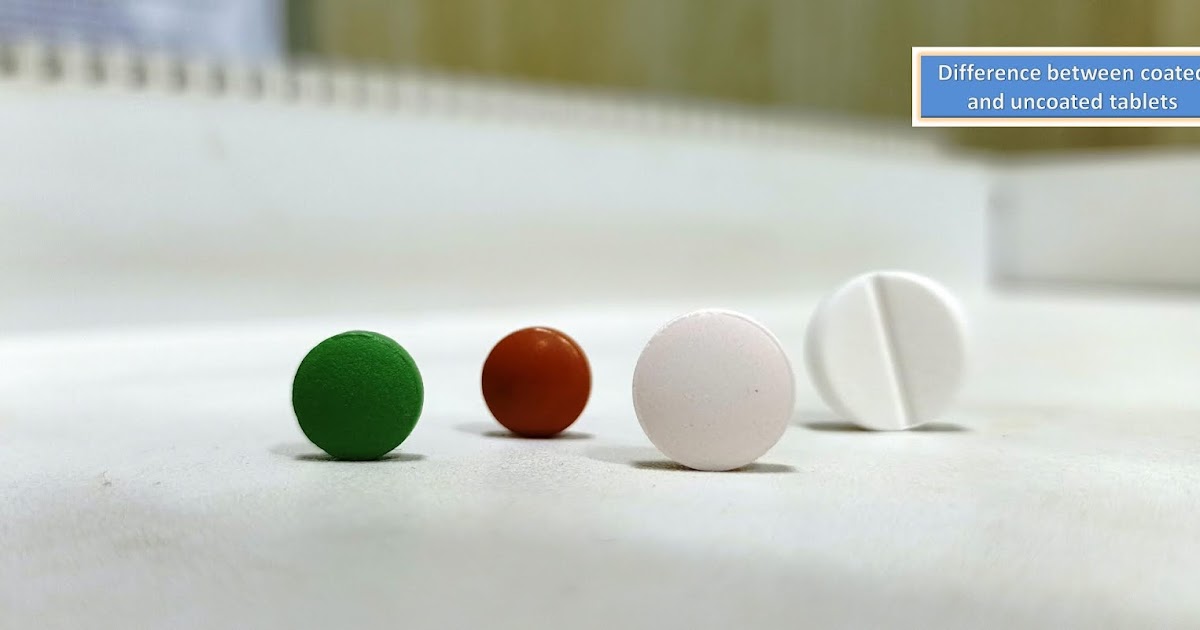

What is the difference between coated and uncoated tablets?

Coated and uncoated tablets are two different types of tablets that are used to deliver medication. Coated tablets have a layer of coating applied to them, while uncoated tablets do not. The coating on coated tablets can be made of a variety of materials, such as sugar, wax, or film. The coating on coated tablets can serve a variety of purposes, such as protecting the tablet from moisture, making it easier to swallow, or controlling the release of the medication. Uncoated tablets do not have any coating applied to them. They are typically made of a single ingredient, such as aspirin or ibuprofen. Uncoated tablets are typically smaller and easier to swallow than coated tablets. They are also less expensive to manufacture than coated tablets.

Coated tablets are often used to deliver medication that is sensitive to moisture or air. The coating on the tablet helps to protect the medication from these elements and ensures that it is delivered to the stomach intact. Coated tablets are also often used to deliver medication that has a bitter taste. The coating on the tablet helps to mask the taste of the medication and make it more palatable. Uncoated tablets are often used to deliver medication that is not sensitive to moisture or air. They are also often used to deliver medication that has a neutral taste.

Coated and uncoated tablets are both effective methods of delivering medication. The type of tablet that is used will depend on the specific medication being delivered and the patient's individual needs.

Coated and Uncoated Tablets

Coated and uncoated tablets are two common types of tablets used to deliver medication. While both types of tablets are effective, there are some key differences between them. Here are seven key aspects to consider when choosing between coated and uncoated tablets:

- Coating: Coated tablets have a layer of coating applied to them, while uncoated tablets do not.

- Purpose of Coating: The coating on coated tablets can serve a variety of purposes, such as protecting the tablet from moisture, making it easier to swallow, or controlling the release of the medication.

- Composition of Coating: The coating on coated tablets can be made of a variety of materials, such as sugar, wax, or film.

- Size and Shape: Coated tablets are typically larger and more difficult to swallow than uncoated tablets.

- Taste: The coating on coated tablets can help to mask the taste of the medication.

- Cost: Coated tablets are typically more expensive to manufacture than uncoated tablets.

- Applications: Coated tablets are often used to deliver medication that is sensitive to moisture or air, or medication that has a bitter taste. Uncoated tablets are often used to deliver medication that is not sensitive to moisture or air, or medication that has a neutral taste.

Ultimately, the type of tablet that is used will depend on the specific medication being delivered and the patient's individual needs. However, by understanding the key differences between coated and uncoated tablets, you can make an informed decision about which type of tablet is right for you.

Coating

The coating on coated tablets plays a vital role in the delivery of medication. It can protect the tablet from moisture and air, making it more stable and less likely to degrade. This is especially important for medications that are sensitive to these elements. The coating can also make the tablet easier to swallow, especially for large or oddly shaped tablets. In addition, the coating can be used to control the release of the medication. This can be done by using a coating that dissolves slowly, releasing the medication over a period of time. This can be useful for medications that need to be taken once or twice a day, rather than multiple times a day.

Coated tablets are often used to deliver medication that is sensitive to moisture or air, or medication that has a bitter taste. Uncoated tablets are often used to deliver medication that is not sensitive to moisture or air, or medication that has a neutral taste. Coated tablets are typically larger and more difficult to swallow than uncoated tablets. They are also more expensive to manufacture than uncoated tablets.

When choosing between coated and uncoated tablets, it is important to consider the specific medication being delivered and the patient's individual needs. However, by understanding the role of the coating on coated tablets, you can make an informed decision about which type of tablet is right for you.

Purpose of Coating

The coating on coated tablets plays a vital role in the delivery of medication. It can protect the tablet from moisture and air, making it more stable and less likely to degrade. This is especially important for medications that are sensitive to these elements. The coating can also make the tablet easier to swallow, especially for large or oddly shaped tablets. In addition, the coating can be used to control the release of the medication. This can be done by using a coating that dissolves slowly, releasing the medication over a period of time. This can be useful for medications that need to be taken once or twice a day, rather than multiple times a day.

Coated tablets are often used to deliver medication that is sensitive to moisture or air, or medication that has a bitter taste. Uncoated tablets are often used to deliver medication that is not sensitive to moisture or air, or medication that has a neutral taste. Coated tablets are typically larger and more difficult to swallow than uncoated tablets. They are also more expensive to manufacture than uncoated tablets.

When choosing between coated and uncoated tablets, it is important to consider the specific medication being delivered and the patient's individual needs. However, by understanding the purpose of coating on coated tablets, you can make an informed decision about which type of tablet is right for you.

Composition of Coating

The composition of the coating on coated tablets plays a vital role in the delivery of medication. The coating can be made of a variety of materials, each with its own unique properties. The most common coating materials include:

- Sugar: Sugar coatings are the most common type of coating used on tablets. They are relatively inexpensive and easy to apply. Sugar coatings can be used to protect the tablet from moisture and air, and they can also make the tablet easier to swallow. However, sugar coatings can be damaged by moisture and heat, and they can also attract insects.

- Wax: Wax coatings are another common type of coating used on tablets. Wax coatings are more resistant to moisture and heat than sugar coatings, and they are also less likely to attract insects. However, wax coatings can be more difficult to apply than sugar coatings, and they can also make the tablet more difficult to swallow.

- Film: Film coatings are the most recent type of coating used on tablets. Film coatings are made of a thin layer of polymer that is applied to the tablet. Film coatings are very resistant to moisture and heat, and they are also very easy to swallow. However, film coatings can be more expensive than sugar or wax coatings.

The choice of coating material will depend on the specific medication being delivered and the patient's individual needs. However, by understanding the composition of the coating on coated tablets, you can make an informed decision about which type of tablet is right for you.

Size and Shape

The size and shape of coated tablets can have a significant impact on their ease of swallowing. Coated tablets are typically larger and more difficult to swallow than uncoated tablets. This is because the coating adds a layer of material to the tablet, making it larger and more difficult to fit in the mouth. In addition, the coating can make the tablet more slippery, making it more difficult to grip and swallow. As a result, coated tablets are often not suitable for patients who have difficulty swallowing pills.

- Size: The size of a tablet is one of the most important factors that affects its ease of swallowing. Larger tablets are more difficult to swallow than smaller tablets. This is because larger tablets take up more space in the mouth and throat, making it more difficult to get them past the back of the throat. In addition, larger tablets are more likely to get stuck in the esophagus, which can cause discomfort or even pain.

- Shape: The shape of a tablet can also affect its ease of swallowing. Tablets that are round or oval are typically easier to swallow than tablets that are oblong or square. This is because round and oval tablets are more likely to roll smoothly down the throat, while oblong and square tablets are more likely to get stuck. In addition, tablets that have a smooth surface are easier to swallow than tablets that have a rough surface.

If you have difficulty swallowing pills, you may want to talk to your doctor about switching to a different type of medication. There are a number of different types of medications that are available in uncoated tablets, which may be easier for you to swallow.

Taste

The taste of medication can be a major deterrent to taking it, especially for children and the elderly. The coating on coated tablets can help to mask the taste of the medication, making it more palatable and easier to take. This is especially important for medications that have a bitter or unpleasant taste.

- Improved Adherence: By masking the taste of the medication, coated tablets can help to improve adherence to medication regimens. This is especially important for medications that need to be taken over a long period of time, such as those for chronic conditions.

- Increased Patient Satisfaction: Coated tablets can increase patient satisfaction with their medication regimen. This is because they are easier to take and have a more pleasant taste.

- Reduced Risk of Side Effects: Some medications can cause side effects such as nausea and vomiting. The coating on coated tablets can help to reduce these side effects by masking the taste of the medication.

Overall, the coating on coated tablets plays an important role in making medication more palatable and easier to take. This can lead to improved adherence to medication regimens, increased patient satisfaction, and reduced risk of side effects.

Cost

Coating tablets adds an extra step to the manufacturing process, which increases the cost of production. The type of coating used, the equipment needed to apply the coating, and the quality control measures required all contribute to the higher cost of coated tablets.

- Type of Coating: The type of coating used can have a significant impact on the cost of production. Sugar coatings are the least expensive type of coating, while film coatings are the most expensive. This is because film coatings require specialized equipment and more stringent quality control measures.

- Equipment: The equipment needed to apply the coating can also affect the cost of production. Some coating equipment is more expensive than others, and some types of coatings require specialized equipment. This can add to the overall cost of manufacturing coated tablets.

- Quality Control: Coated tablets require more stringent quality control measures than uncoated tablets. This is because the coating can affect the stability and Wirksamkeit of the medication. As a result, coated tablets must be tested more thoroughly to ensure that they meet the required standards.

The higher cost of coated tablets is often justified by the benefits that they provide. Coated tablets are more stable and less likely to degrade, they are easier to swallow, and they can mask the taste of the medication. As a result, coated tablets are often the preferred choice for patients who have difficulty swallowing pills or who are taking medications that have a bitter taste.

Applications

The choice of whether to use coated or uncoated tablets depends on a number of factors, including the stability of the medication, the taste of the medication, and the patient's individual needs. Coated tablets are often used to deliver medication that is sensitive to moisture or air. This is because the coating protects the medication from these elements and ensures that it is delivered to the stomach intact. Coated tablets are also often used to deliver medication that has a bitter taste. The coating on the tablet helps to mask the taste of the medication and make it more palatable.

Uncoated tablets are often used to deliver medication that is not sensitive to moisture or air. They are also often used to deliver medication that has a neutral taste. Uncoated tablets are typically smaller and easier to swallow than coated tablets. They are also less expensive to manufacture than coated tablets.

Understanding the difference between coated and uncoated tablets can help you to make an informed decision about which type of tablet is right for you. If you have any questions about coated or uncoated tablets, be sure to talk to your doctor or pharmacist.

FAQs on Coated and Uncoated Tablets

This section addresses frequently asked questions (FAQs) on coated and uncoated tablets, providing concise and accurate answers.

Question 1: What is the difference between coated and uncoated tablets?

Answer: Coated tablets have a layer of coating applied to them, while uncoated tablets do not. The coating on coated tablets can serve a variety of purposes, such as protecting the tablet from moisture, making it easier to swallow, or controlling the release of the medication.

Question 2: Which type of tablet is better, coated or uncoated?

Answer: The type of tablet that is better depends on the specific medication being delivered and the patient's individual needs. Coated tablets are often used to deliver medication that is sensitive to moisture or air, or medication that has a bitter taste. Uncoated tablets are often used to deliver medication that is not sensitive to moisture or air, or medication that has a neutral taste.

Question 3: Are coated tablets more expensive than uncoated tablets?

Answer: Yes, coated tablets are typically more expensive to manufacture than uncoated tablets. This is because the coating process adds an extra step to the manufacturing process.

Question 4: Can coated tablets be crushed or broken?

Answer: No, coated tablets should not be crushed or broken. This is because the coating can be damaged, which can affect the release of the medication.

Question 5: What should I do if I have difficulty swallowing coated tablets?

Answer: If you have difficulty swallowing coated tablets, you can try taking them with a glass of water or with food. You can also talk to your doctor or pharmacist about switching to a different type of medication.

Question 6: How should coated tablets be stored?

Answer: Coated tablets should be stored in a cool, dry place away from heat and moisture. They should also be stored in their original container.

By understanding the answers to these FAQs, you can make informed decisions about the use of coated and uncoated tablets.

Transition to the next article section: For more information on coated and uncoated tablets, please refer to the following resources:

- [Resource 1]

- [Resource 2]

- [Resource 3]

Conclusion

Coated and uncoated tablets are two common types of tablets used to deliver medication. The type of tablet that is used depends on the specific medication being delivered and the patient's individual needs. Coated tablets are often used to deliver medication that is sensitive to moisture or air, or medication that has a bitter taste. Uncoated tablets are often used to deliver medication that is not sensitive to moisture or air, or medication that has a neutral taste.

Coated tablets have a number of advantages over uncoated tablets. Coated tablets are more stable and less likely to degrade, they are easier to swallow, and they can mask the taste of the medication. However, coated tablets are also more expensive to manufacture than uncoated tablets.

Ultimately, the decision of whether to use coated or uncoated tablets is a medical one that should be made in consultation with a doctor or pharmacist. However, by understanding the difference between coated and uncoated tablets, you can make an informed decision about which type of tablet is right for you.

Sticky Lubes: Your Ultimate Guide To Find The Best Lubricant

Definitive Guide To Caudal: Meaning And Usage

How To Cancel Costco Connection Magazine Quickly And Painlessly

Is Your Packaging Safe From COVID19? Process AG Plastic Packaging

Chrominfo Difference between coated and uncoated tablets

Sozial Einschlag heilig types of tablet coating process Aufzeichnung